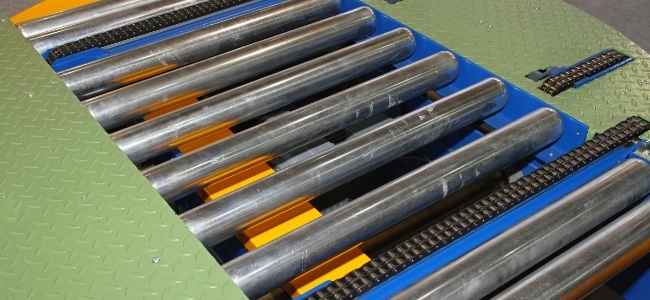

Gravity conveyor rollers is the name given to unpowered rollers that are able to transport products solely through the use of the momentum of gravity, with no additional power required to move materials. Gravity conveyor rollers come fitted in a slightly inclined frame that allows the freely running rollers to use nothing more than gravity to transport products.

One of the most affordable and simplest material handling system types, gravity conveyor rollers work by just allowing the item to roll along on their upper surface, as the parts will start to move across the rollers when mounted upon a slight decline.

There are a number of uses for and benefits gained from the use of gravity conveyor rollers. Gravity conveyor rollers come with unique uses, as is the case with the great majority of conveyor rollers, and are a perfect for use in a wide array of different industries.

Gravity conveyor rollers are particularly popular within the type of industries that require the transportation of boxed products including the likes of food and drinks, logistics and many others. Any location that makes use of much light to medium loading as a part of their day-to-day operations can make use of gravity conveyor rollers including warehouses, distribution centres and production facilities.

The majority of gravity conveyor rollers are between 1.5 to 1.9 inches in diameter, though 2.5 and 3.5 inch diameters can be found for extreme duty applications. The systems are easy to configure and are able to be bought online and used either permanently or temporarily on account of their light nature. Roller curve units can be used to negotiate corners.

Why use gravity conveyor rollers?

There is a large array of different uses for gravity conveyor rollers, which can also be modified and adapted in order to better suit individual requirements. Gravity conveyors can be made use of in a wide range of different tasks such as the transportation of small and large boxes, crates, tote boxes and pallets.

The industries that make use of gravity conveyor rollers as a part of their everyday operations include food and drink handling, logistics, manufacturing, packaging, postage and couriers.

There are different types of gravity conveyor rollers that may have different capacities for the amount of weight they are able to carry, as well as different materials that are used in their manufacture.

Gravity conveyor rollers can be found in materials that will match what is required by a particular industry. For example, stainless steel would be perfect for a gravity conveyor roller for easy cleaning, which is why the food and drink industry often makes use of it.

However gravity conveyor rollers can and are made with a variety of different materials such as PVC.

Factors that will need to be kept in mind when purchasing a gravity conveyor roller include the width and length of the conveyor and the frame style.

Gravity roller conveyors are an excellent and simple way to move items without the need to use electrical power.